Does the damp proof course go above or below thermal insulation elements?

Where an insulation element is used to address thermal bridging heat losses, damp proof course detailing must take into account the product's characteristics.

Above or below?

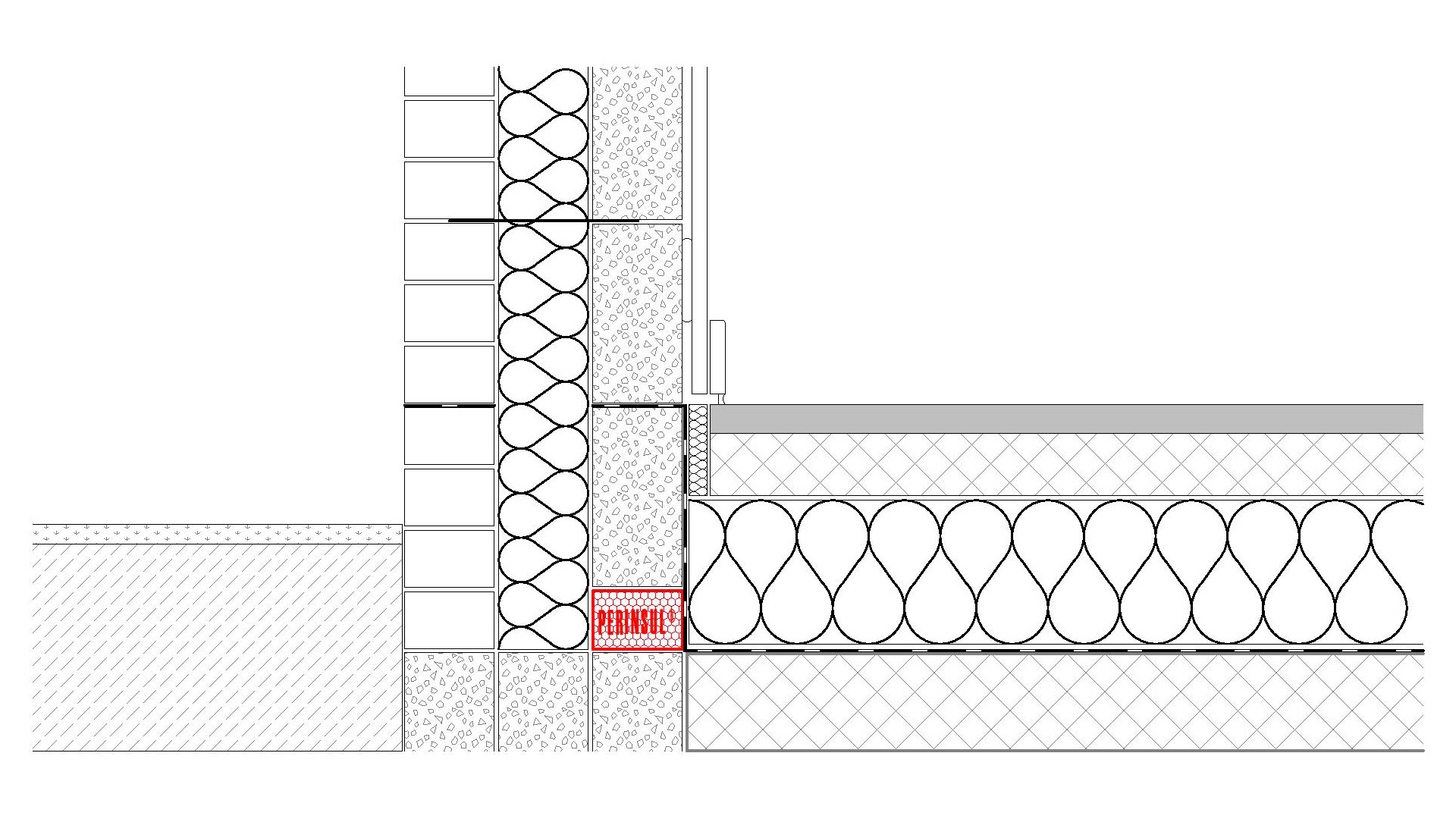

A load-bearing insulation element installed as a thermal bridging solution in a ground floor junction detail should be positioned in accordance with the manufacturer's instructions.

Different products are manufactured using various materials, which respond in distinct ways depending on the conditions they are exposed to.

A product made from cellular glass, such as FOAMGLAS® PERINSUL HL, has a closed cell structure that is watertight. It can therefore be positioned above or below the damp proof course (DPC) in the masonry of the external wall but is not a replacement for damp proofing measures.

What different ground floor details need to be considered?

An essential part of a ground floor construction is the damp proof membrane. Where moisture levels in the ground are normal, the membrane keeps groundwater from entering the building. National building regulations set requirements for protecting buildings from moisture.

At the junction between a ground floor construction and the external walls of a building, the damp proof membrane must lap with the damp proof course in the walls to provide consistent protection to the building.

Where a load-bearing insulation element like FOAMGLAS® PERINSUL HL is used to address thermal bridging heat losses, the detailing of the damp proof membrane and damp proof course must take into account the characteristics of the insulation product. This is true of masonry and timber framed external walls, and below window and door sills.

What standards apply to damp proof course detailing?

Although a watertight product like PERINSUL HL insulation can be installed above or below the damp proof course to align with the ground floor insulation, it does not replace damp proofing measures. It should be used in conjunction with a conventional DPC, specified in accordance with relevant standards.

CP 102:1973 Code of practice for protection of buildings against water from the ground remains a current guidance document, though parts have been superseded. The same is true for BS 743:1970 Specification for materials for damp proof courses.

BS 8215:1991 Code of practice for design and installation of damp proof courses in masonry construction should be referenced alongside both of the above documents. For bitumen and polythene damp proof courses respectively, refer to BS 6398:1983 and BS 6515:1984.

Relevant clauses of BS 8004:2015+A1:2020 Code of practice for foundations should be also referenced. Other standards that may be mentioned in connection with any of the above include Eurocode 7 (BS EN 1997), which deals with geotechnical design, and BS 8102:2009, which deals with below ground waterproofing (a distinct discipline from DPC detailing.

To get the best results from using PERINSUL HL load-bearing insulation element, ensure it is protected from mechanical damage and prolonged contact with soil, ground water and surface water. For detailing or installation advice, contact Owens Corning FOAMGLAS® through the dedicated PERINSUL HL website.