What are the benefits of using load-bearing thermal insulation blocks?

There are 5 building performance benefits, for designers and for contractors, when specifying load-bearing thermal insulation blocks.

5 performance benefits for designers and contractors

1. Better energy performance

2. Healthier, more comfortable buildings

3. Easier compliance and meeting more stringent standards

4. Better junction detailing with no significant changes to working practices

5. Reasurance of a long-term solution that will continue to perform

There has never been greater awareness of the need for the energy efficiency and low U-values that thermal insulation can help to deliver.

Despite this, thermal bridging can still be overlooked in designs and when a project on site is underway.

Better energy performance with thermal insulation blocks

Greater awareness of the importance of thermal insulation and its contribution to energy efficiency has led to better performing buildings and lower rates of heat loss. As unwanted and unnecessary heat loss is reduced in one area, so heat loss in other areas comes to represent a larger proportion of the overall total.

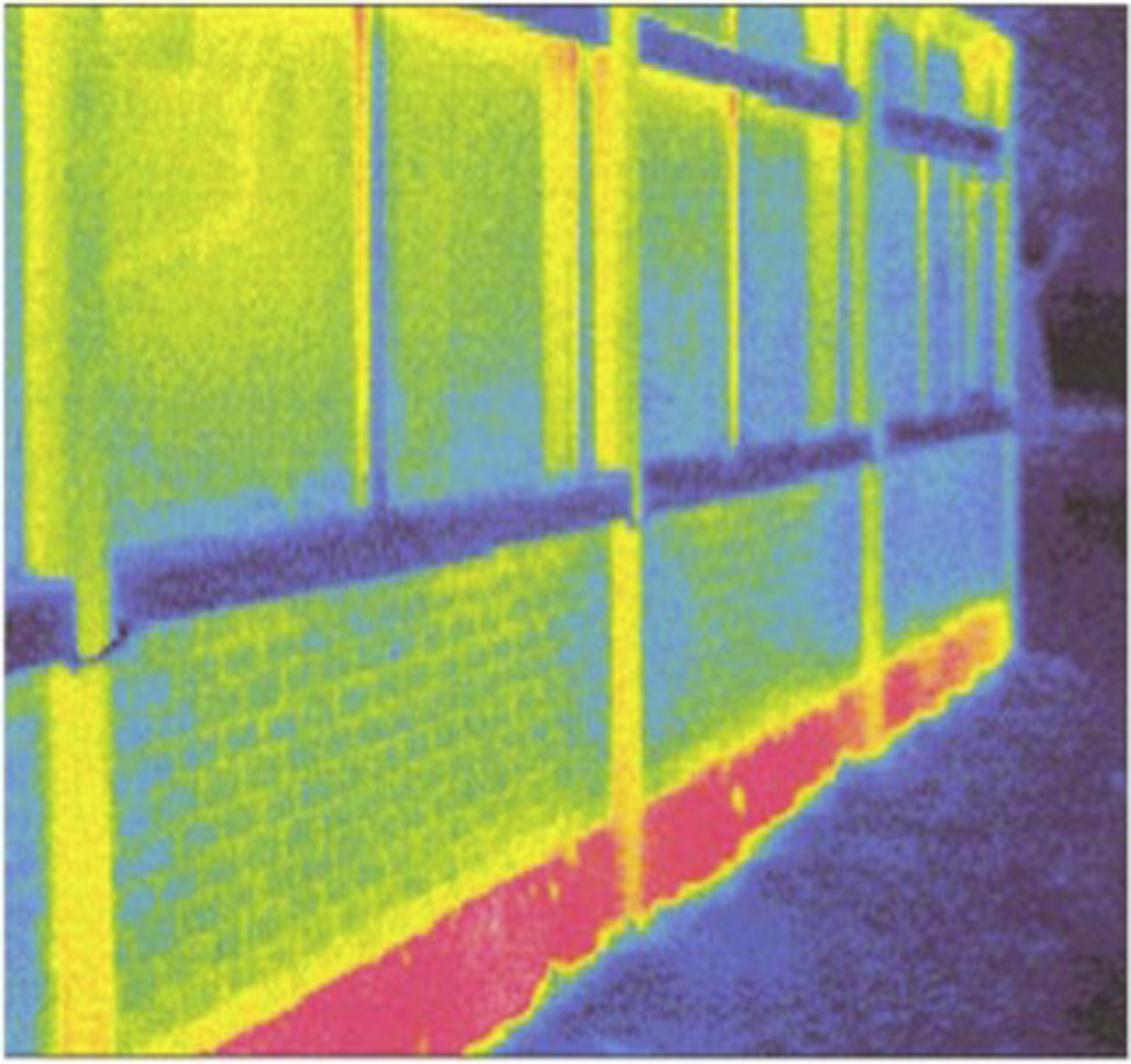

This is the case with the thermal bridges that occur at junctions between well-insulated construction elements. Poorly designed and constructed thermal bridges with minimal insulation result in buildings with much higher rates of heat loss, and therefore much higher energy bills, than is necessary.

The good work of insulating the floors, walls and roofs is undone by a lack of attention to detail. Load-bearing thermal insulation blocks represent a proven solution, that when installed as part of junction detailing, provides an effective heat loss solution at these details.

Load-bearing thermal insulation blocks deliver healthier, more comfortable buildings

Beyond the raw facts and figures of heat loss values and energy consumption figures, there is the more subjective aspect of building occupant comfort. Thermal bridges at poorly detailed junctions create localised ‘cold spots’ and draughts, as warm air finds the path of least resistance. Occupants therefore must turn up the heating to try and combat the effect.

If a junction detail performs poorly enough, the reduction in surface temperature may cause condensation to form. The condensation could be unseen in the building fabric. Alternatively, it could be in evidence on the inside surface of the junction, with harmful black mould then occurring.

Use of thermal insulation elements can eliminate this potential health hazard.

Easier compliance and meeting more stringent standards

National building regulations represent a minimum standard of construction to ensure the health and safety of building users and to reduce energy consumption. This represents a potential temptation to do the bare minimum to achieve compliance and gain building sign-off.

Paying attention to thermal bridging and making the effort to use a load-bearing insulation element at junction details can make regulatory compliance easier. By reducing the impact of linear thermal bridging in compliance calculations, the pressure to use very thick layers of insulation elsewhere is reduced.

A better balance of thermal efficiency is achieved across the whole building fabric, rather than trying to compensate for a lack of attention to detail. This is to the benefit of overall building performance and occupant comfort.

Better junction detailing with no significant changes to working practices

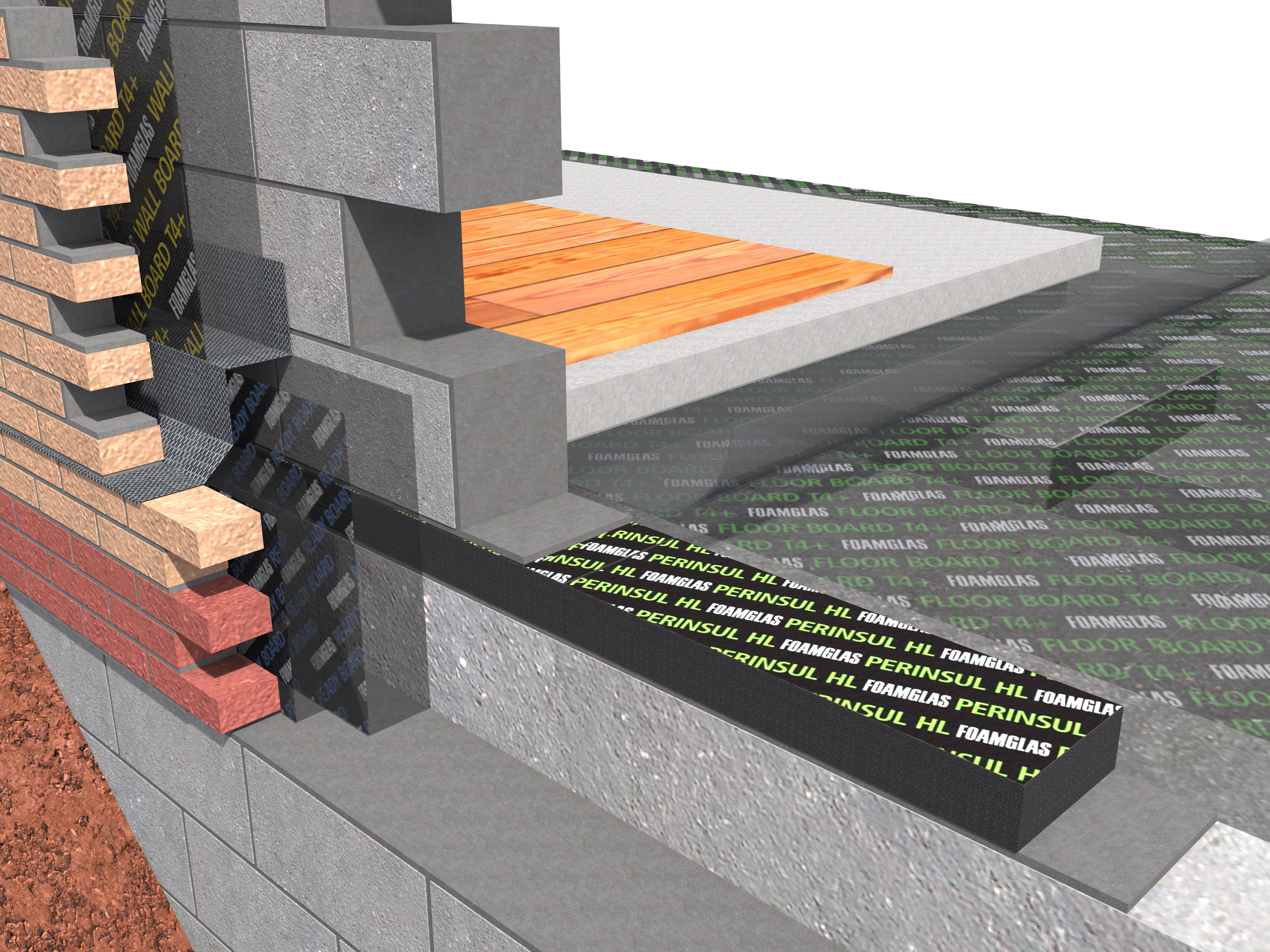

Arguably, one of the barriers to achieving this better balance is a misconception that high performance junctions are complicated to detail and construct. A load-bearing element like FOAMGLAS® PERINSUL HL improves the thermal performance of junction details while keeping the same or similar design detailing.

When the project reaches site, the elements are laid as part of laying standard masonry units. No special training is required, and masonry contractors can put their existing skills to use and improve the overall energy efficiency of the building at the same time.

Reassurance of a long-term solution that will continue to perform

Thermal insulation elements are installed as part of junction details that have a structural function. The elements must therefore deliver their thermal performance without compromising the stability of the building. FOAMGLAS® PERINSUL HL is manufactured from cellular glass insulation, which has a high compressive strength and will not distort or degrade over time.

PERINSUL HL has been tested specifically as a load-bearing insulation element, rather than only an insulation product. It provides an effective link between adjoining building elements, maintaining continuity of insulation while bearing structural building loads - for the life of the building and beyond.

PERINSUL HL can be used at the base of external walls, below internal masonry partitions, in flat roof parapet details, and below window and door sills. 2D and 3D numerical modelling calculations are available, allowing thermal performance values to be entered directly into compliance calculations. The same calculations also check the local surface temperatures at the junction detail, ensuring there is no risk of condensation.

To find out more, download the PERINSUL HL whitepaper, or request a CPD seminar with our expert team. Alternatively, contact us with any technical enquiries.