How to avoid cold bridging and thermal bridging in construction

Excess heat loss due to thermal bridging can be avoided through attention to detail at design and construction stage. With well-insulated building fabric, thermal bridges become responsible for a greater proportion of total heat loss. Addressing them becomes key to good building performance.

Designing out thermal bridges

Simplicity is often key to good energy efficient building design. Features like bay windows and dormer windows might achieve a certain aesthetic, but they also introduce extra complications.

Similarly, complicated building forms with a lot of junction details or structural design elements increase the risk that a continuous thermal envelope will be difficult to achieve, with the unwanted extra heat loss that comes with that.

It’s easy for designers to fall into the trap of assuming the contractor on site will work out the best way of installing the insulation as shown on the drawing - be it at junctions, around steel beams, or in bay and dormer windows - without considering the practicalities of how the design will be achieved.

A recommended tactic for designers is to take a section drawing and trace the thermal envelope around the whole building. Anywhere that it’s necessary to lift the pen from the page reveals an area of the building fabric in need of attention.

Avoiding thermal bridges on site

Even where a building is designed to eliminate thermal bridging as much as possible, poorly installed insulation can unwittingly create a thermal bridge. A floor, for example, could be considered relatively simple to insulate - but insulation boards laid with gaps between them, allowing heat to escape, would create a thermal bridge.

Educating site operatives is an important part of achieving low-energy building performance. Clear, high quality drawn information is a good start, and explaining specification choices to avoid inferior product substitutions is important.

Working with contractors to establish the best way to construct a detail, especially where the solution proposed is new and unfamiliar, is much better than allowing the approach of ‘we’ve always done it this way’.

Not only does this collaborative approach result in better construction quality, it provides useful learning for both designer and contractor to take on to future projects.

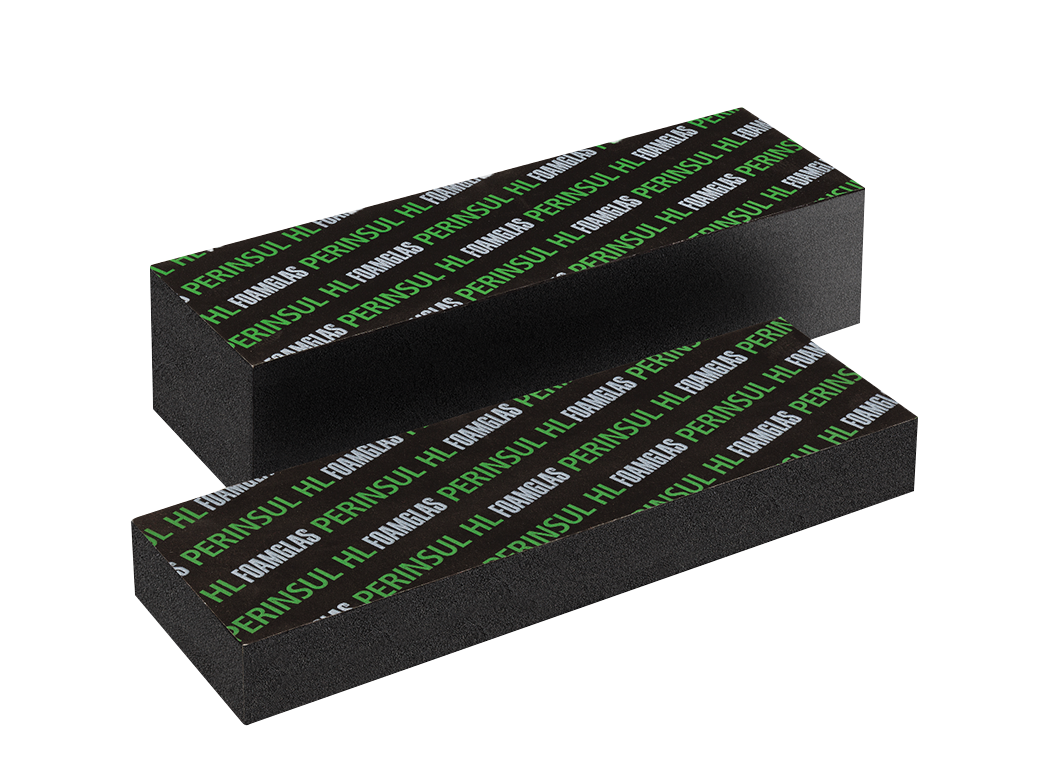

About PERINSUL HL

PERINSUL HL is a thermal bridging solution developed by FOAMGLAS®. The cellular glass insulation has the compressive strength required to bear the structural loads of a building, and the thermal performance to reduce heat loss due to thermal bridging.

Used in hard-to-insulate junction details, PERINSUL HL maintains continuity of insulation without compromising structural stability. It drastically reduces linear thermal bridging at the base of external walls, in parapet details, and below door and window sills.

For more information on PERINSUL HL and how it can benefit your next project don’t hesitate to contact our team.