Where can I get technical data for thermal insulation elements

used to address thermal bridging at junctions?

Manufacturers’ data sheets should always be the first port of call for technical data about load-bearing insulation elements designed for use as thermal bridging solutions.

Other sources of information for designers, specifiers and installers include third-party certification and test results. This blog post looks at what data is useful, and the different ways in which it can be used such as in psi value calculations and structural calculations.

Technical assessment

of thermal bridging solutions

Independent third-party certification verifies the technical performance of a construction product. The content of a certificate, like a BBA certificate, gives advice on regulatory compliance, installation and fitness for purpose that is complementary to the data sheet offered by the manufacturer.

The British Board of Agrément (BBA) have issued certificate number 14/5111 for PERINSUL HL insulation, manufactured by Owens Corning FOAMGLAS®. Like many construction products, the manufacture of most types of thermal insulation is covered by a harmonised European standard. This allows a Declaration of Performance (DoP) to be issued as part of CE marking procedures.

Thermal bridging solutions do not necessarily fall into that category and are assessed by alternative means. PERINSUL HL insulation was assessed as a block to prevent thermal bridging, rather than a ‘conventional’ insulation product. Granting of a European Technical Assessment (ETA) followed verification against a European Assessment Document (EAD). PERINSUL HL insulation therefore carries the CE Mark, as a further demonstration of its fitness for purpose.

Product characteristics

of a thermal bridging solution

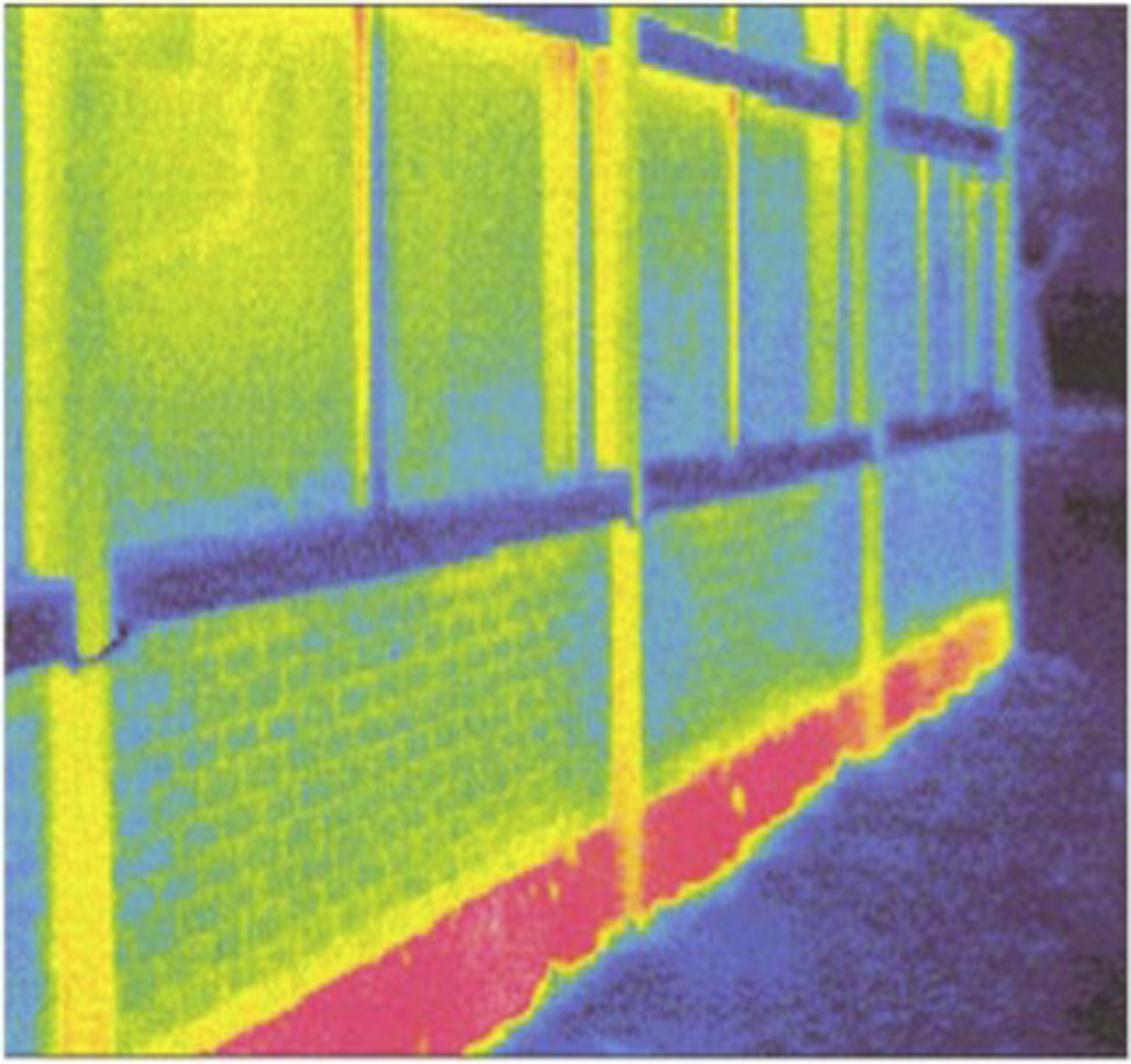

PERINSUL HL is made from cellular glass - a waterproof, non-combustible thermal insulation. It is designed for installation at junction details, reducing thermal bridging heat losses, so its thermal performance is one of its essential characteristics.

Its thermal performance is used in 2D and 3D numerical modelling to calculate heat loss paths through the junction detail. The resulting psi value is multiplied by the length of the junction detail to work out the total heat loss for that junction type, which can then be entered into compliance calculations and other building performance modelling software.

Modelling the junction detail also allows surface temperatures to be calculated, checking that the insulation element also contributes to reducing the risk of condensation.

As a load-bearing element, PERINSUL HL is designed to be used at the base of external walls, below internal partition walls, in flat roof parapet details, and below window and door sills.

Providing the correct information regarding compressive strength is essential for structural engineers to make their calculations accurately and with confidence.

All technical data and documentation relating to PERINSUL HL is available on the downloads page of the dedicated FOAMGLAS® PERINSUL HL website, through which you can also contact Owens Corning FOAMGLAS® directly.